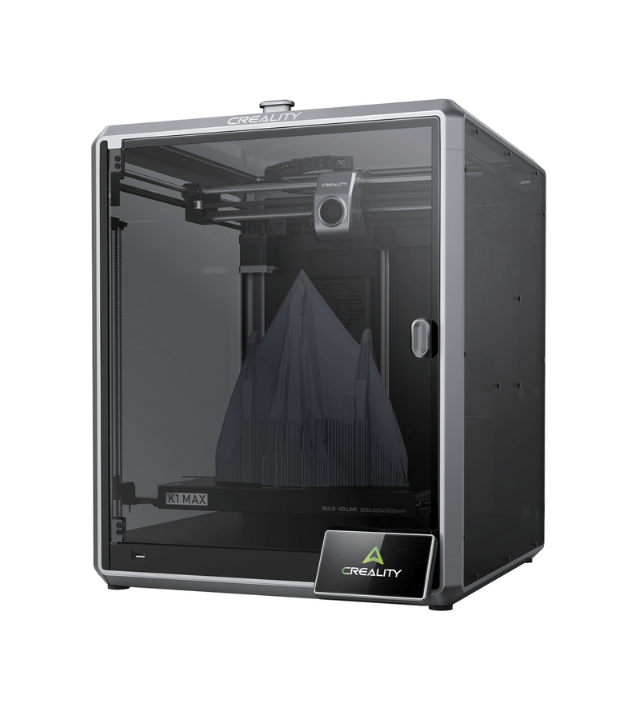

Creality K1 Max Imprimante 3D – Capacité et Vitesse Max

11,990.00 DH

- 600mm/s Printing Speed& 300x300x300mm Large Build Volume

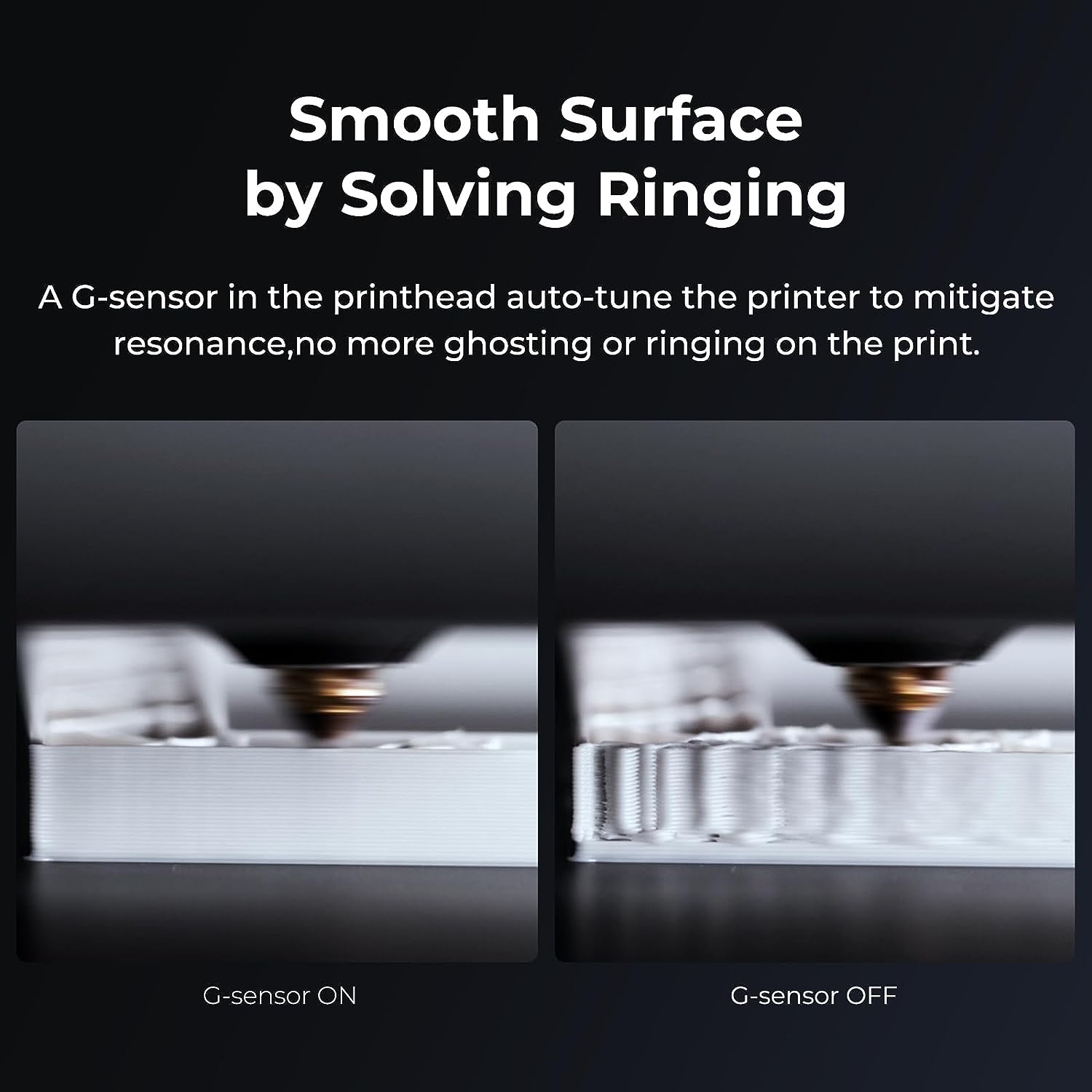

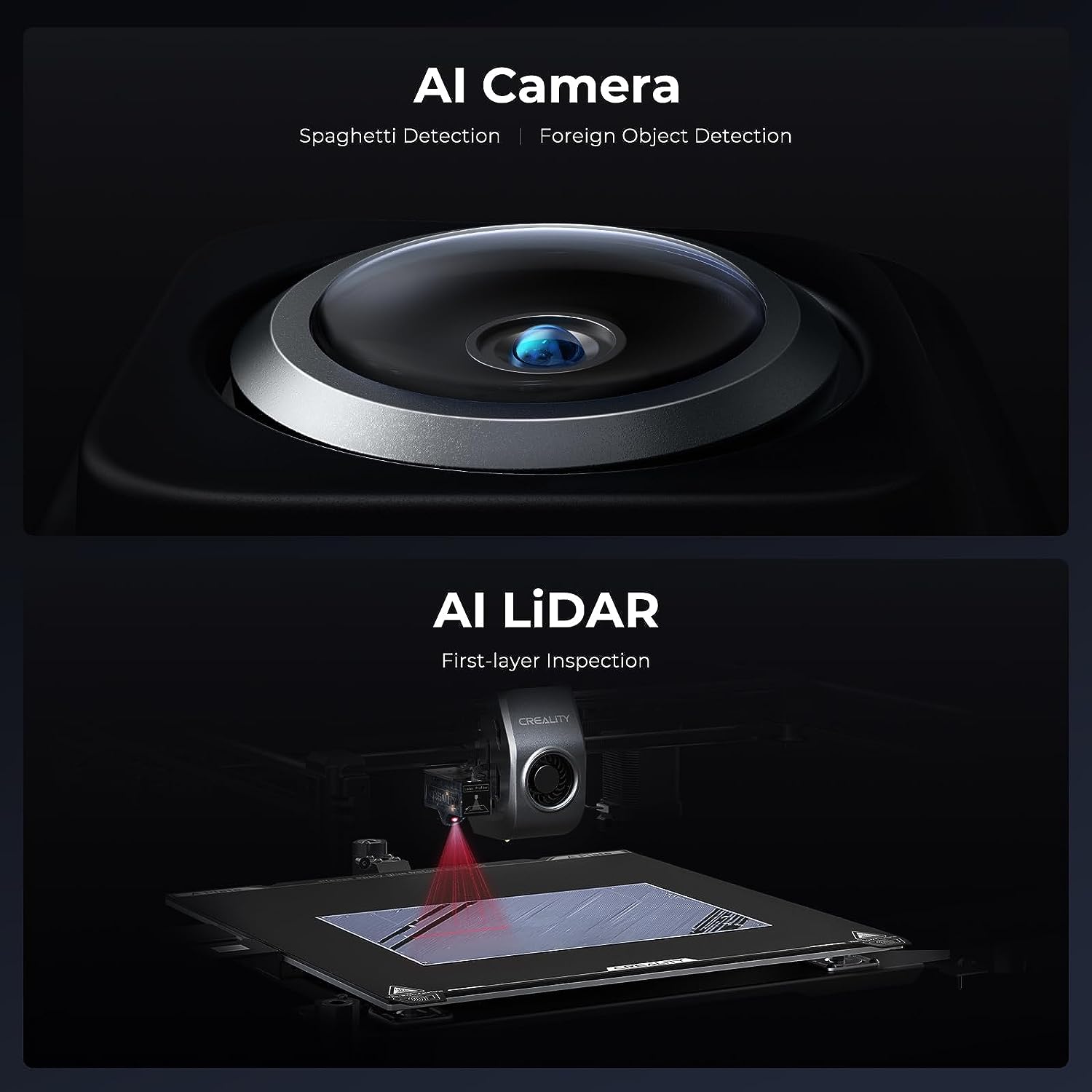

- Al-assisted Carefree Printing: AI LIDAR | Al Camera |Creality OS | Multi-printers Control

- Hands-free fully automatic bed leveling and calibration

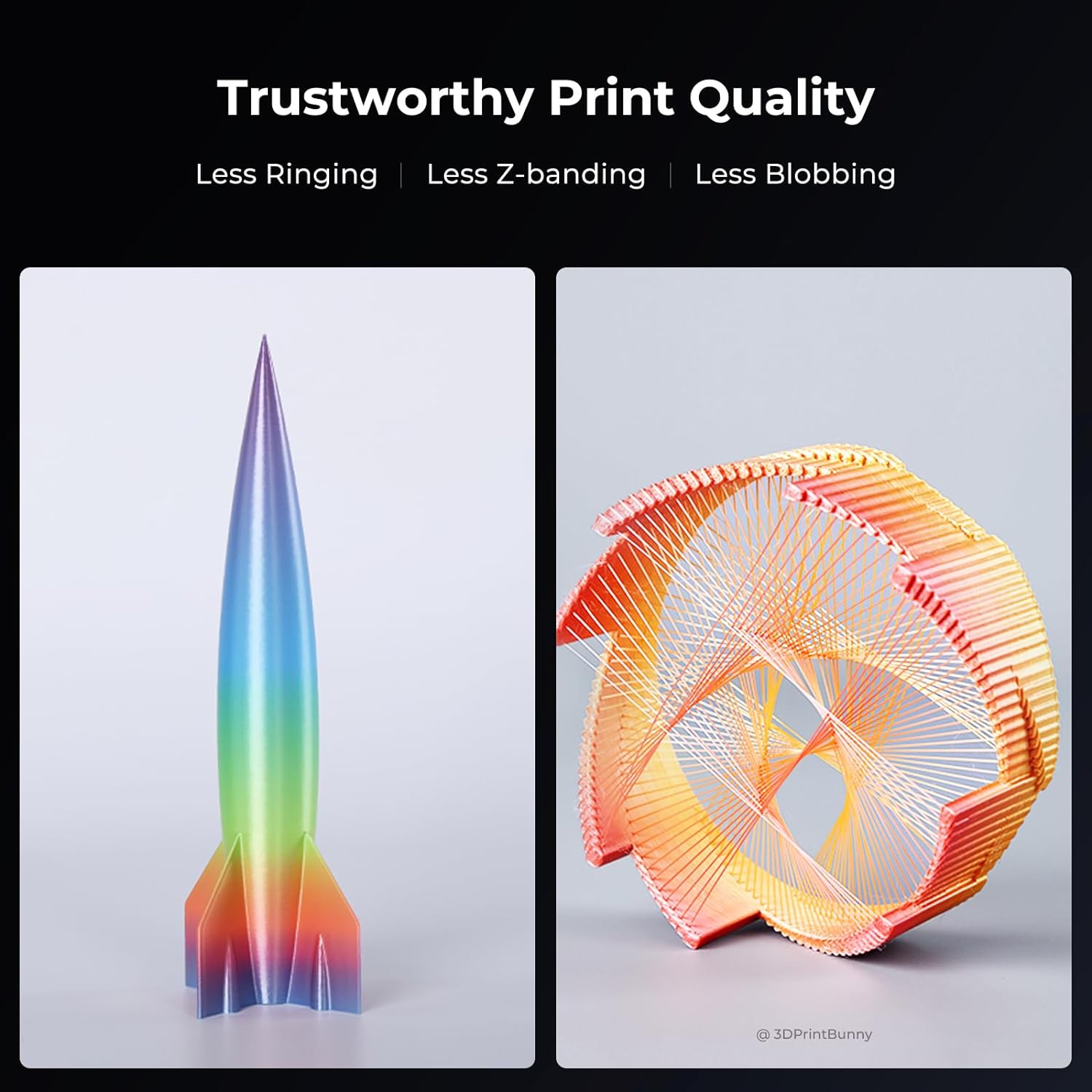

- Upgraded Z-axis for precise positioning, minimizing Z-banding and enhancing texture subtlety

- One-button automatic detection with instant reporting of any machine errors

En stock